1. Light guide films and sheets

2. Light solutions with Silicone Keypads

3. SoftLogo

4. Lighting solution for assembly

5. Light filter and lens

Light up your product.

Lighting is becoming increasingly important for successful branding of products. These applications require general back and/or functional lighting.

Abatek has an innovative portfolio of technologies designed to support and develop the shape of both attractive and functional lighting solutions.

Be inspired by some examples below and discuss new ideas or improvements with your nearest Abatek partner.

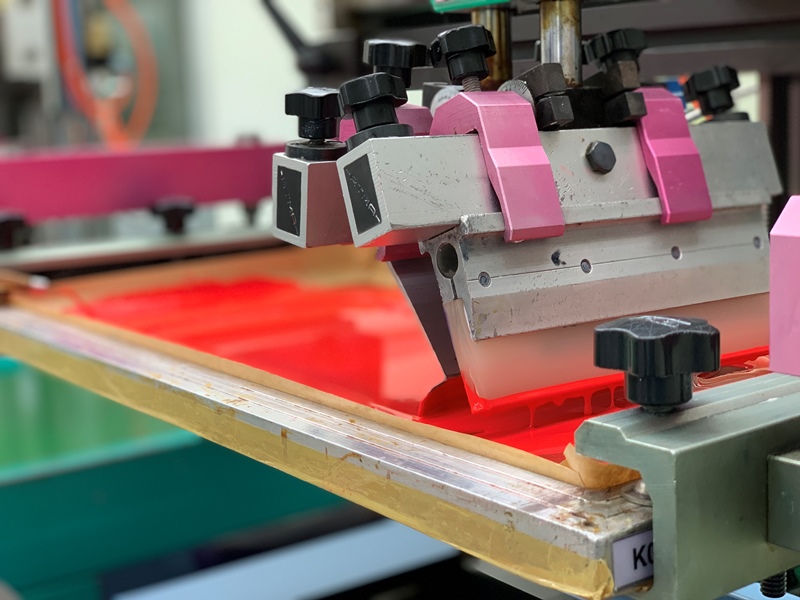

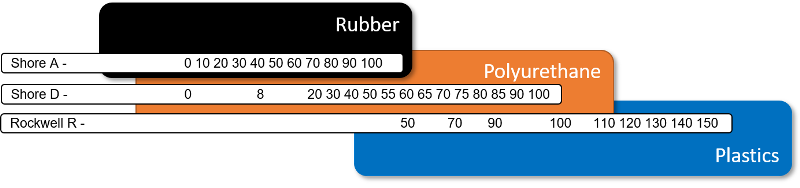

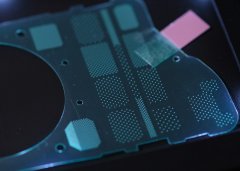

Light guide films and sheets

Light guide films and sheets.

Bring out the light appearance for areas or segments whilst reducing the number of LEDs.

A Light Guide Film (LGF) or Sheet (LGS) optimizes use of energy and the overall cost.

Each LGF or LGS not only reduces the number of LED's usualy needed but also spreads the light more efficiently where desired.

In conclution: Fewer LED's means less energy consumption and less heat.

|

|

LGF

|

Ultra thin lighting solution.

Light Guide Film (LGF) is an ultra-thin lighting solution for very slim applications and can be placed directly over metal domes.

|

1_Technologies_Lighting_LGF

|

LGS

|

Enjoy design freedom.

Light Guide Sheet (LGS) can have a glossy or matt surface in any 3D shape.

The LGS also offers a sealing function.

|

1_Technologies_Lighting_LGS

|

Contact

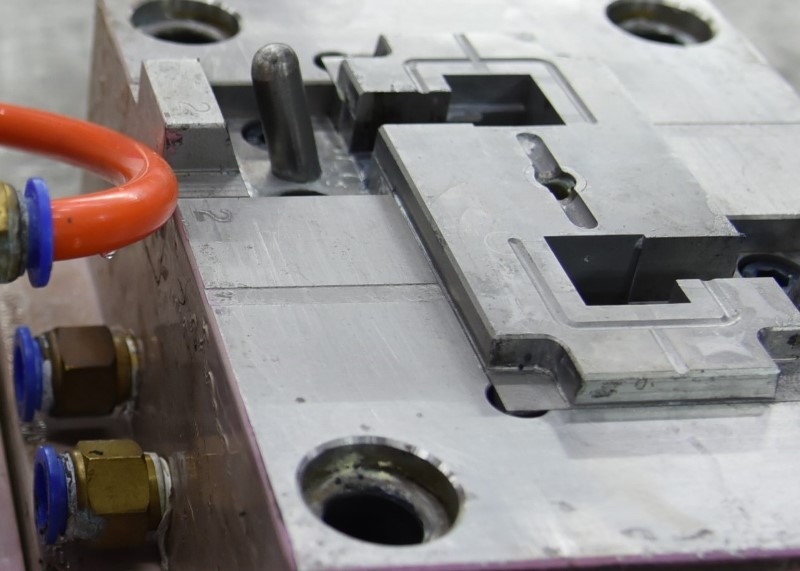

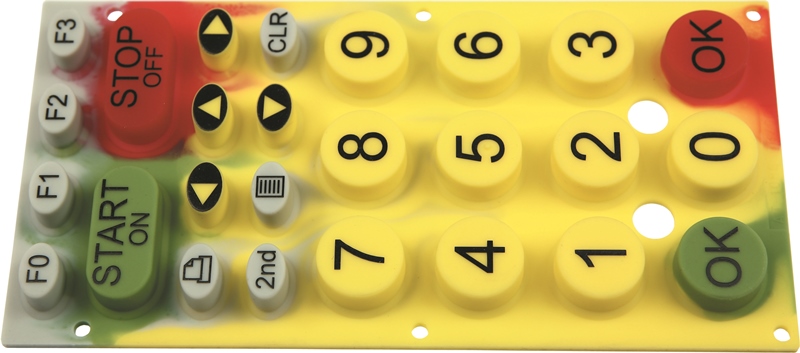

Light solutions with Silicone Keypads

Add value to the Silicone Keypad.

Illumination technology, light guiding and light shielding is an important topic within the world of HMI.

Abatek offers high quality equipment for precisely laser etched graphics on silicon parts.

As a result out of this technology defined areas can easily be back lighted.

|

2_Technologies_Lighting_solutio

|

LED Windows

|

Sealing LED light pipes within the Keypad.

Thin windows for indicator LED's: When the LED window is very thin it almost appears transparent. This characteristic can be used to design a sealed window for indicator LED's.

The almost non-transparent silicone on the side wall will still prevent from light leakage.

For additional protection - if required - the surface can be covered with an additional color layer whereas the LED windows are cleared by a laser process.

|

2_Technologies_Lighting_solution_LED

|

Transparent key top

|

A-Surface with silicone part

For A-Surface parts the backlight can be adjusted by the percentage of the color pigments added into the base material. The LED can be positioned directly under each key for example by using a ring pill.

|

2_Technologies_Lighting_solution_Transparent

|

Light pipe

|

Transmission of light.

The most commonly used technique is to guide the light through a silicone pipe to the surface.

See picture A.

As a light pipe acrylic glass instead of silicone can be inserted into the keypad.

See picture B.

|

2_Technologies_Lighting_solution_Light_pipe

|

Night Design & Dead Front

|

Night Design & Dead Front Panels.

This technology is also known as Night Design / Dead Front Panel and basically uses the “Disappearance Effect”.

All lit areas disappear when the source of light is turned off and all that remains is a homogeneous surface.

Only when the light is switched on the desired function/information is visible.

Abatek offers the Black Panel Solution as stand-alone or as part of a complete design combined with our Light Foil or Light Sheet.

|

2_Technologies_Lighting_solution_Night_Design

|

Contact

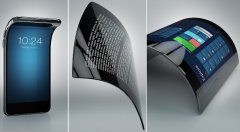

SoftLogo

Flexible and robust logo.

Strengthen the effect of your logo and build in an illuminated non-shattering 3D emblem.

Discover new design freedom for 3D objects with a self-healing and closed surface.

- Any shape and hardness

- Any structure and look i.e. leather, wood, carbon and more

- Self-healing

- Closed surface – 100% water proof and easy to clean

Distinguish the look by combining various colors and surface structures to emphasize your brand.

- Unique: High gloss / matt / brushed - also seamless

- Any color - also combined

- Night Design & Dead Front

|

3_Technologies_Lighting_Flexible

|

SoftLogo

|

Exciting new design possibilities.

This 100% closed water proof & chemical resistant surface offers never previously seen design possibilities.

Abatek even makes backlighting with special effects such as blinking, dimming, alternating colors and Night Design & Dead Front possible.

|

|

Prime Line

|

Unprecedented design freedom for illuminated logos.

Enhance the standard SoftLogo with a self-healing surface.

This solution allows the seamless combination of any color - even matt adjacent to high gloss is possible.

|

|

Contact

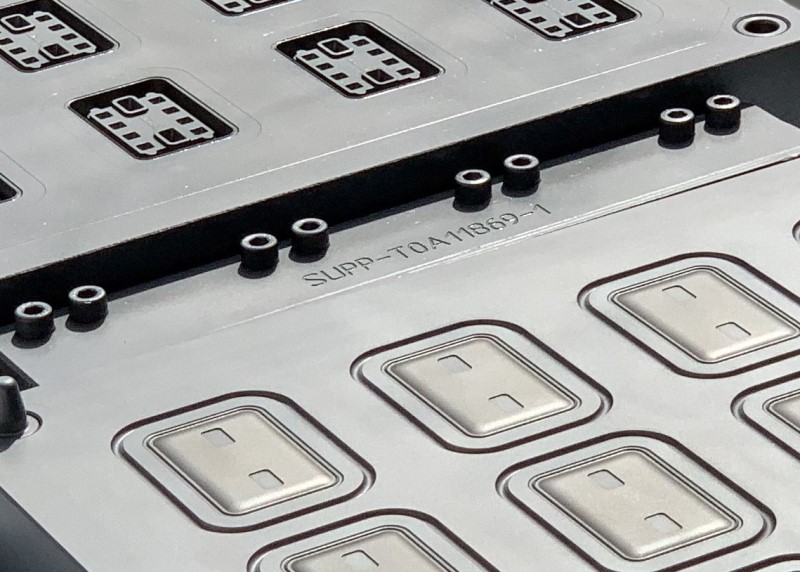

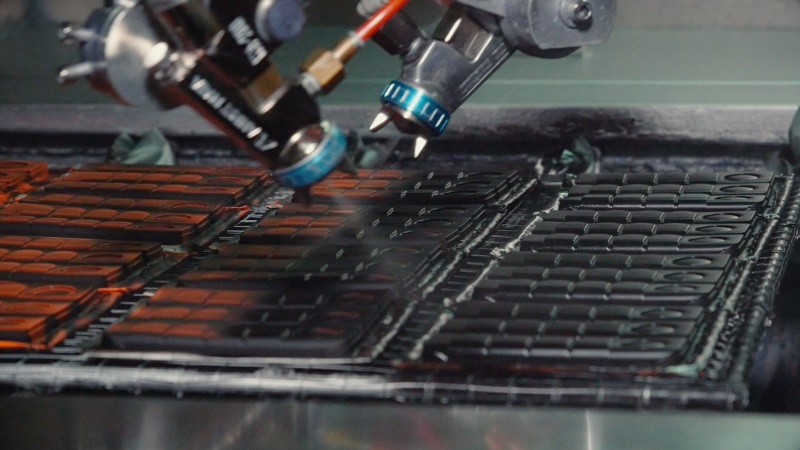

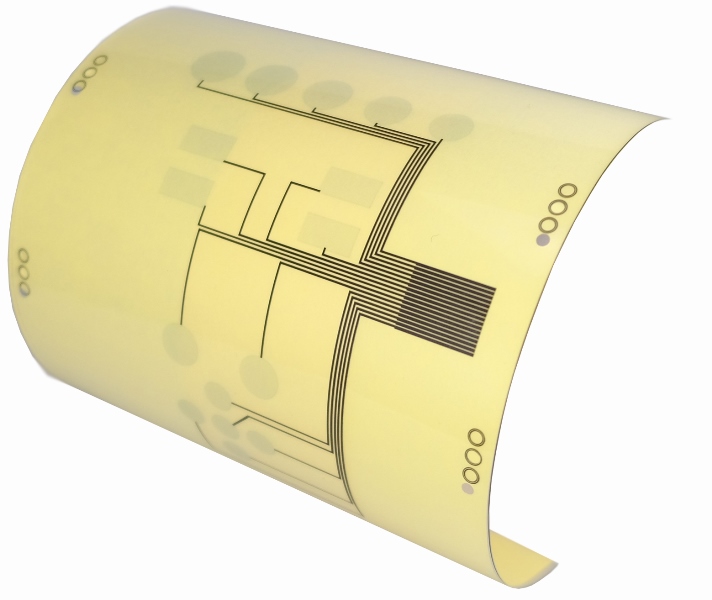

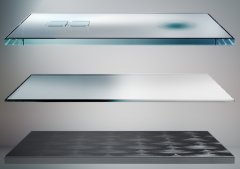

Lighting solutions for assembly

Enhance the Lighting.

Aside from coloring the materials Abatek can assemble light guides with other In-House components like silicone or plastic parts.

This allows the optimization of the product with full design freedom.

Thanks to the automated assembly Abatek can ensure reliable and high quality product during project life time.

|

4_Technologies_Lighting_Lighting_solutions_for_assembly

|

Contact

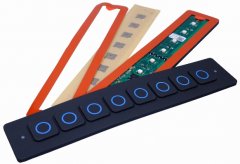

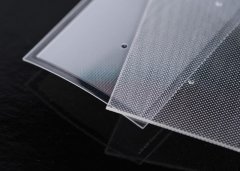

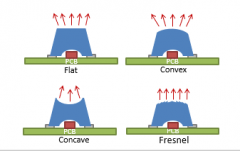

Light filters and lenses

Simple SMT technology light filters and lenses.

In order to filter or shift the wavelength of LED's a simple SMT placeable silicone shape can be soldered above of the LED on PCB. In addition the silicone shape can serve as a lens.

The sketches on the right show the concept of SMT placeable silicone lenses and color filters.

Blue represents the customized silicone.

|

5_Technologies_Lighting_Light_filter_and_lens

|

Contact